WEST801.HMSP Repair of double-sided operation defect due to improper mounting of the pull plate centering

"Do not open the door from the inside"

When I looked it up from the address and property name, it was an old apartment built 38 years ago. It's probably a knob lock. I was told that the door would not open from the outside or from the inside.

Damage to the parts of the lock case is also considered, but anyway, I will head to the site.

When I arrived at the scene, it was the knob lock of WEST801. The body case was a thin MIWA HMSP (for DT25-29).

There is a US military base nearby.Therefore, it was a soundproof door, thick and with Gremont locks.Is thin HMSP used to prevent interference with Gremont locks?

It seems that the management company and another locksmith have come many times so far, but it seems that it has been neglected for several months without any improvement. What does that mean? (As a result, it turned out to be a basic installation failure.)

The WEST801 is a universal replacement knob lock and is always in stock. However, it is a cylinder set that requires careful installation.

First of all, I will disassemble the interior side, but when I removed it from the pull plate, I felt a little uncomfortable. (Is it slightly slanted?)

After loosening it a bit, the deadbolt action started working normally. If I tighten it too hard, it will reoccur. The aging deterioration of the main body case was not visually confirmed.

(Is this due to excessive tightening of the pull-up plate, or is the length of the spindle part too long and the parts are interfering with each other?)

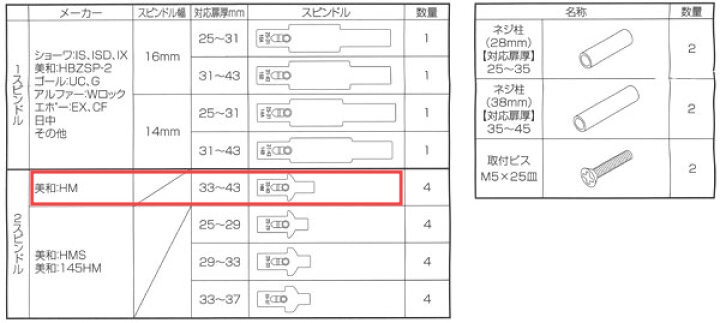

I confirmed that the door thickness is DT36mm. Comparing the thumbturn side knobset spindle parts from the table below, it was found that the correct parts were installed. (To remove the spindle parts, considerable disassembly is required.)

I also disassembled the knob set on the cylinder side and checked the engraving on the spindle part, but it was a proper part. (Reassembly is quite troublesome, but it is done carefully and carefully.)

No abnormalities were found in the main body case.

At this point, the only thing that remains is the cause around the attracting plate. If this plate is overtightened, it will not be possible to center the thumbturn side knob set, and the operation will become heavy.

Reattach it to the draw plate and it will screw in smoothly this time not slanted. The first discomfort was that the thumbturn side knobset was installed diagonally. (It was caused by improper installation by some contractor)

While firmly checking the direction of the square core of the knob set on the cylinder side, set it so that it can be locked and unlocked by turning the key 180 degrees.

(This is also the most important point when installing the WEST801. When the cylinder rotates 360 degrees, return the square core 180 degrees. Otherwise, the thumbturn and the latch bolt will move together. It's bad.)

In the end, the true cause was that the pull plate was tightened too much and the centering was insufficient. Furthermore, the knob set was attached diagonally to the pull plate, so the square core could not be turned completely.

It took me about an hour to get to this point, but I finally found the cause and fixed it.